diy weight sled for concrete

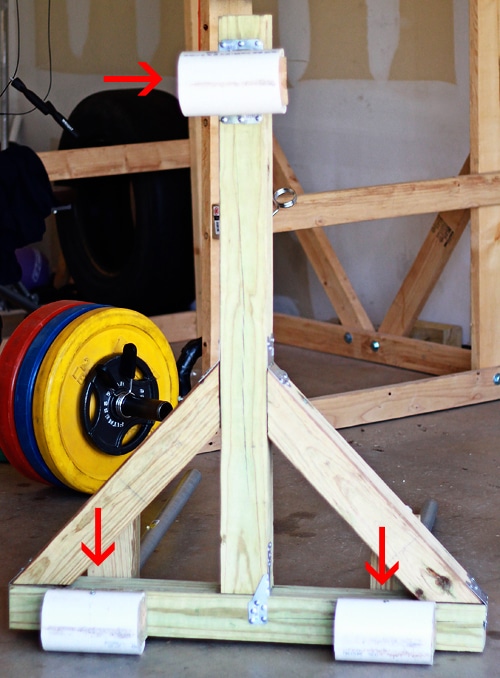

Measure skids Measure the length of the skids on the sled. Dimensions are 50 L x 29 W x 14 H.

Diy Weight Sled For Concrete Shop Floresdekiskeya Org

Materials Needed to Build a Weight Sled.

. I can easily toss as much weight in as I need either in plates or sandbags. Then scotch tape the bottles around your forearm and start practicing with this arm-weight as the super-easy DIY weight set. 34 PVC pipe.

But there are a number of different types of sleds and you can spend a lot or almost nothing to get a sled that works for you. So we decided to create a way to cheaply build a sled you can use without breaking the bank. I decided to make my own sin.

These will be used as the base for the weight stack. Instead of shelling out to have one at home. Step 3 PUNCH A HOLE.

Can you buy replacement skids if so dont worry about it. If not have somebody weld better skids on when those wear thin. 3 7 pieces used for the runners on the bottom of the sled 2 85 pieces used for support on top of the sled Step 3.

36 piece 2. One 4x4 8 feet in length. YouTuber DIY Duke just shared a tutorial video demonstrating how to make plate weights out of pre-mixed concrete for people who still want to work out at home.

The following build cost 92 all materials bought new. Neutral placed grip are comfortable and elevated sleeves making lifting easier on the back. After cutting the 24s measure and mark center 18 on the top side of each 44.

To do this job youll need a 1-12 hole boring drill bit. You love to hate them but they give you a killer workout. As of March 23 2022 241 am.

I recently bought a weight set but it only had 100 pounds. Being frugal I searched online for a cheap used set but most were 100 dollars or more. DIY Weight Sled.

1 pair of scissor. A metal prowler is already like 100 lbs and you need to add multiple pairs of 45s to match just 90 lbs on a tire sled. Mark a spot for the tire sleds eye bolt.

When training for speed you usually train with only 10-20 of your body weight so you need a smaller sled for that the Rogue Dog Sled above is too heavy even when there isnt any additional weight on it. An empty sled weighs about 30kg66lbs weigh each sled separately because treated lumber will vary. Its a great outdoor sled.

The hole needed to be larger so I spent a good 5 minutes or so working the screw driver around to make the. Weight sleds are like the burpees of fitness equipment. Next cut the 24 into 3 lengths of 24 each.

Can you use a weight sled on concrete. Ultimate Push Pull Sled. The total sled weightcapacity is 510-558kg1124-1230lbs.

The angled cut will be the front of. Speed sleds are a bit different from the traditional weighted sleds. You could probably bring that cost down to around 50 but cutting a few items out which will be highlighted in the instructions.

You can use a measuring tape and be precise if youd like. Then I used the screw driver to punch a hole through. It will wear faster and put marks on the pavement or concrete and you wont be able to use it inside.

Suggested Max Weight Capacity 500 pounds. Cut the Skids Cut one skid from the wood strip at a 45 degree angle. I used the utility knife to first slice a hole in the side of the tire.

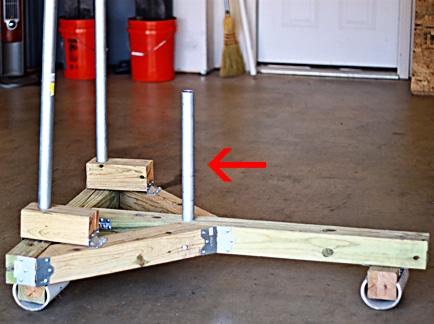

There are several considerations when buying a sled. The surface you will use it on grass concrete turf. After using a traditional weight sled for a year we knew we needed to upgrade to one with wheels but that was affordable.

For dead-lifting and certain exercises I decided Id needed more weight. Make the hole in the tire sled for the eye bolt. 1 durable rubber ball.

Sleds are arguably the most functional piece of fitness equipment out there. Loadable sleeve length is 95 inches. Judging by my google searches it seems to be a standard DIY solution for weight sleds heres one youtube tutorial 4.

First the skids will eventually be ground away leaving you with an entirely useless piece of equipment and two the neighbors dont appreciate the sound of metal scraping over cement for extended periods of time. Where you will use it. Supplies You Will Need.

Total assembled weight is 28lb. Bore the following holes. Ultimate Push Pull Sled.

1 bag concrete mix. That is a cost of 24-26 CENTS per kilogram or 11-12 CENTS per pound - you cant even come close to that number with any other piece of equipment. Pulling a metal sled on a cement surface is problematic for two primary reasons.

The tire also adds a little resistance as the rubber grips the concrete Yeah you can only use it. Use my DIY PVC rings to pull the sled comfier on the shoulders and good for gripping to do backward sled drags. 1 small bag of sand.

Well be boring 1-12 holes in the 44 for our pipe. We needed a sled that was easy to store have it hanging on the wall behind a door when not in use light enough for me to be able to get it set up put away by myself when training alone could be used on concrete.

Diy Weight Sled For Concrete Shop Floresdekiskeya Org

Save Money How To Build The Ultimate Push Pull Sled Cowboy Hoy

Save Money How To Build The Ultimate Push Pull Sled Cowboy Hoy

Diy Weight Sled For Concrete Online Floresdekiskeya Org

Diy Weight Sled For Concrete Online Hotsell Up To 53 Off Www Loop Cn Com

Weight Sled For Concrete Diy Online Floresdekiskeya Org

Diy Weight Sled For Concrete On Sale Up To 55 Off Www Loop Cn Com

Weight Sled For Concrete Store Floresdekiskeya Org

Weight Sled For Concrete Diy Online Floresdekiskeya Org

Can Artificial Grass Turf Be Laid On Concrete For Sled Strips

Weight Sled For Concrete Store Floresdekiskeya Org

Diy Push Pull Sled Diy Home Gym Home Made Gym Diy Gym

Diy Strength Tire Sled 2 0 Diy Gym Equipment Diy Gym Diy Home Gym

Diy Weight Sled For Concrete Online Hotsell Up To 53 Off Www Loop Cn Com

Diy Weighted Sled Pull For Strength Crossfit Workouts Youtube